For better bonding of the components on to the circuit board through soft soldering an acidic substance known as flux is added for ensuring tight soldering connects.

Types of circuit board soldering.

First of all solder comes in many forms.

While soldering the tip becomes hot and melts the solder.

And maybe the solder paste if you want to do smd soldering.

The iron is designed with an end piece shaped like a pencil tip.

Pcb soldering is another term for the process of soldering electrical circuit boards.

The circuit board is rigid but it connects to a layer of the flex circuit board.

Information in this article applies broadly to different solder types.

There are two dominant types of solder.

The last type the rigid flex printed circuit boards are both rigid and flexible.

There are two main types of solder.

However it is still flexible.

The lead based solder.

Solder on a pcb can be thought of as connective tissue.

A soldering gun is a larger unit with a handle used to grip the device.

While there are many different ways you can complete the soldering process the most basic explanation of the soldering.

The right solder secures an electrical connection that lasts the life of the circuit and avoids points of failure.

It serves as the conductive glue that sticks components to substrate and brings continuity to the circuit board it s hard to imagine what modern electronics would be like without this convenient low melting point alloy at our disposal.

This type of soldering is one of the most basic techniques that anyone wishing to work with electronics and electrical circuits must learn.

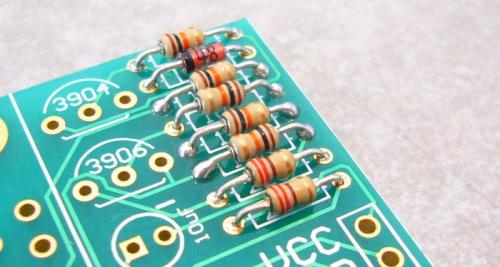

The type of solder used in electrical bonding contain different materials with the most common one composed of 60 tin and 40 lead thus the name 60 40 solder.

As a hobbyist you will only need to get acquainted with the solder wire.

The main practical difference between the two is the melting.

Pellets bars paste and wire.

Use a soldering iron for intricate soldering of electronic parts and circuit boards.

It is a confusing concept but the main idea behind these boards is that you use them with items that require a strong board.

A gas or electric powered soldering iron is used for soft soldering process and the bond created as a result is often weaker than other types of soldering.